If you read our beginner’s guide to transportation management systems (TMSs), then you know that these dynamic software solutions include a broad range of capabilities. Of these various functions and features, one of the most valuable capabilities of a TMS solution is that it can precisely track key performance indicators (KPIs).

While everyone can agree that tracking supply chain KPIs is a good idea, it can be tough to decide which metrics to focus on. If you attempt to track too many supply chain KPIs, you can experience information overload and lose out on critical business insights.

To help you get the most out of your TMS technology, the team at R2 Logistics has created this guide to supply chain KPIs. Below, we outline 5 metrics that every business should be tracking.

Must-Track Supply Chain KPIs

The top 5 supply chain KPIs that you should be paying attention to are:

1. Perfect Order Rate

The perfect order rate is a testament to your fulfillment team’s attention to detail, efficiency, and quality control practices. This supply chain KPI measures the percentage of orders that are accurate and complete. In order to qualify as a “perfect order,” the order must also be in flawless condition.

A high perfect order rate will lend itself to improved customer satisfaction. When your customers know that your goods consistently arrive in perfect condition, they will develop feelings of loyalty toward your brand. This loyalty can lead to an increased customer lifetime value and improved profitability for your company.

2. Cash-to-Cash Cycle Time

Of the various supply chain KPIs you should be tracking, cash-to-cash cycle time is undoubtedly one of the most important. This metric reveals how much time passes between purchasing materials and receiving funds for your finished products. Naturally, the goal is to make the cash-to-cash cycle time shorter.

If you have an excessively lengthy cash-to-cash cycle time, then your working capital will be tied up for an extended period. This situation could create cash flow issues and endanger business continuity.

3. Fill Rate

Fill rate is another straightforward but critical supply chain KPI. This metric refers to the percentage of orders that are completely fulfilled during the initial shipment. If a customer’s order has to be split into two or more shipments, then your fill rate will decrease.

If desired, you can track several different types of fill rate metrics separately. A few examples include unit fill rate, line fill rate, and order fill rate. Tracking these specific metrics will help you pinpoint potential inefficiencies and address fill rate issues that may be impacting customer satisfaction.

4. Customer Order Cycle Time

If your goal is to optimize customer satisfaction (and it should be), then you must track customer order cycle time. This important metric tracks the time between receiving an order and delivering goods to the customer.

Customer order cycle time provides insights into your supply chain’s responsiveness. If your customer order cycle time is longer than industry norms, then you should explore ways to increase supply chain agility.

Excessive customer order cycle times must be addressed promptly, as leaving this issue unresolved can have a serious impact on client satisfaction.

5. Freight Bill Accuracy

Shipping improper quantities of goods or delivering the wrong products to customers can cut into your profit margins. It can also reduce trust in your brand and lead customers to seek other suppliers.

If you want to avoid these issues, then you should be tracking freight bill accuracy. This metric gauges how precise your freight bills are.

While achieving perfection across all orders is extremely difficult, you should strive to maximize your freight bill accuracy. Additionally, use this metric to identify sudden dips in accuracy, which may indicate a more serious issue with your fulfillment processes.

How to Simplify Supply Chain KPI Tracking

Choosing which supply chain KPIs you want to track is only the first step. After you have identified which metrics are relevant to your company and business goals, you need to find a way to monitor them seamlessly.

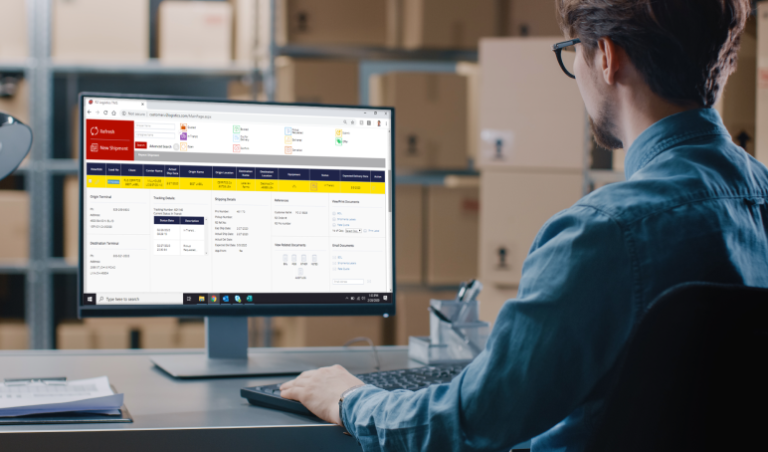

While there are many ways to facilitate supply chain KPI tracking, the most pragmatic approach involves adopting cloud-based transportation management software.

In addition to improving your ability to track supply chain KPIs, a TMS solution offers many other benefits. This technology can boost overall supply chain efficiency, improve inventory management, and increase order fulfillment accuracy.

On its own, TMS technology can empower you to leverage KPIs, gain valuable insights into your business, and move closer toward your growth goals. However, if you want to maximize the efficacy of this investment, you should pair the tech with comprehensive managed transportation services from R2 Logistics.

As a premier third-party logistics company, R2 Logistics can assist with everything from TMS deployment to customizing your supply chain management strategy.

To learn more about how our TMS solution can facilitate supply chain KPI tracking, provide a competitive advantage, and further your digital transformation, schedule a demo today.